Not known Incorrect Statements About American Plastics

Table of ContentsThe Facts About American Plastics Revealed8 Simple Techniques For American PlasticsThe smart Trick of American Plastics That Nobody is DiscussingUnknown Facts About American PlasticsExcitement About American Plastics

This consideration is especially essential for applications that entail high-pressure liquids. The range and range of the task also play a considerable role in dimension option. Bigger tasks may need pipelines with higher diameters to efficiently disperse liquids over fars away. Variables such as terrain problem, the potential for environmental stress, and the installment setting need to influence the pipe dimension to make certain an effective, long-term application.

Involve with expert guidance to validate your option and adapt as required for optimum results. Equipped with this expertise and the workable steps laid out, you are fully equipped to make enlightened choices when picking HDPE pipe dimensions for your projects. Your focus to detail in this choice procedure will go a lengthy method in ensuring the efficiency, safety and security, and cost-effectiveness of your piping systems.

Rumored Buzz on American Plastics

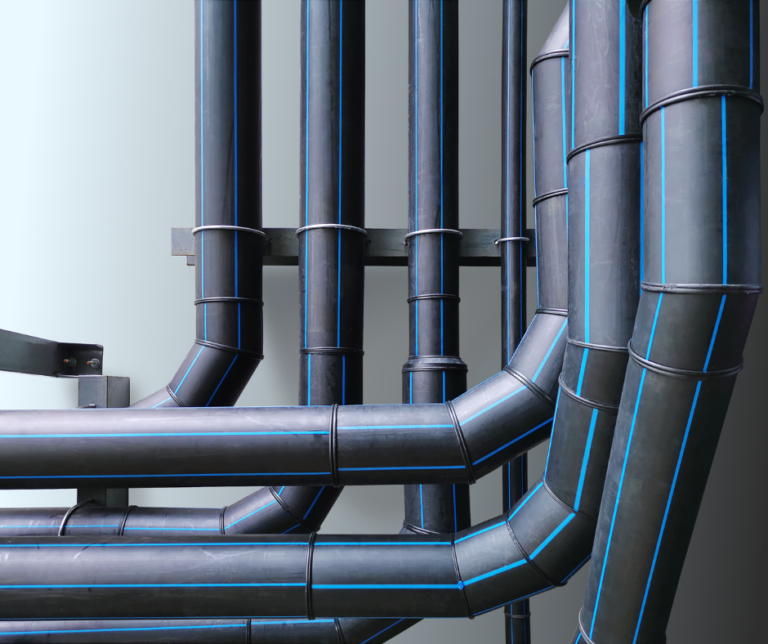

Since HDPE is light-weight and chemically inert, it can deal with fluid and gas transportation with minimal maintenance. HDPE pipes are commonly adopted across a series of fields as a result of their versatility and strength. One of one of the most usual usages for HDPE pipe remains in water systems. HDPE's deterioration resistance makes it excellent for both potable and non-potable water circulation, whether in municipal networks or personal systems.

: HDPE pipes are joined via warm blend, developing a seamless, uniform link as solid as the pipeline itself. This leak-proof joint is critical in gas and water circulation, where leakages might result in hazardous circumstances or pricey waste.: HDPE pipes are lighter than traditional steel pipelines, making them less complicated to deliver and mount.

Our easy and rapid purchasing procedure and reliable logistics guarantee you receive your 4-inch HDPE pipe in the shortest feasible time (hdpe pipe suppliers Midland TX). Our after-sales group is available 24/7 to assist with any kind of concerns you may come across, making sure tranquility of mind.

PE 80 is for simple commercial applications like gas and water, while PE 100 supplies lasting strength and efficiency for harder usages. For a succinct take a look at applications, below are some of the most typical sorts of HDPE piping and their applications. Piping systems use PE 32 or PE 40 for low-pressure applications.

American Plastics Things To Know Before You Buy

PE 80 has a product immune to fractures, so it appropriates in applications susceptible to fracturing, like sewer system and water distribution lines. PE 100 is likewise resistant to splits, and 100 N/mm2 is the minimum necessary stamina. As pointed out, classifications of HDPE piping consist of small pressure, product, and color coding.

Suppliers generate pipes with various stress qualities (PN grades). This shows the stress in bars the pipe can sustain with water at 68 degrees Fahrenheit. The pressure grades adhere to European standards, and they are: PN 2.5 max stress 2.5 bar PN 4max pressure 4 bar PN 6max pressure 6 bar PN 10max pressure 10 bar PN 16max stress 16 bar The shade codes that indicate the pressure grade are yellow for PN4, red for PN6, blue for PN10, and eco-friendly for PN16.

Pipeline providers offer sizing guides with extra info like wall surface density and mass. Quality control follows ISO requirements managing the product design and minimum necessary stamina (MRS) of pipes.

Industries consider nominal stress, product, and other parts when identifying which pipes to make use of - https://soundcloud.com/americanplastics. Today, you'll see high-density polyethylene pipelines in water supply, gas distribution, farming, and a lot extra.

Rumored Buzz on American Plastics

It's worth keeping in mind that gas needs high resistance to stress, making PN-16 to PN-2 quality pipes ideal for procedures. The farming industry utilizes HDPE pipelines for watering and water drainage.

Mining business utilize pipelines for slurry transportation and dewatering. The best part is that companies can utilize general PN course pipelines for this application.

For starters, HDPE pipelines are remarkably long lasting and can last a lengthy time with very little upkeep. They're likewise resistant to deterioration, chemicals, and UV rays. https://anyflip.com/homepage/zksxz. HDPE pipes are likewise cost-efficient contrasted to various other piping products. They're less prone to damage, which cuts repair service costs! HDPE pipelines are lighter than standard pipelines for better handling and transport.

The smart Trick of American Plastics That Nobody is Discussing

Whether you're a specialist, designer, or do it yourself fanatic, this post will give you with the understanding to make informed decisions and attain optimum outcomes. When it comes to picking the appropriate HDPE pipe for your project, comprehending the PSI rating is of utmost significance. The PSI ranking determines the stamina and stress ability of the pipe, showing how much stress it can look at this website endure without failing.

The PSI score of an HDPE pipeline determines its ability to deal with various stress degrees. Pipes with higher PSI scores can stand up to higher pressure, making them appropriate for applications that entail greater liquid or gas pressures. On the other hand, pipelines with lower PSI scores are perfect for low-pressure applications.